LA NOSTRA STORIA

Dal 1981

Stagnoli nasce negli anni ‘80. Come tutte le imprese vincenti, anche Stagnoli è nata da un’idea, l’idea di utilizzare le materie plastiche per applicazioni meccaniche come le cremagliere per cancelli. Questa idea è stata perseguita da sempre sia dal sig. Francesco Albiero, che tuttora offre all’azienda le sue preziose consulenze e il suo prezioso know how, sia dallo staff tecnico-commerciale, che oggi rappresenta il cuore pulsante di Stagnoli. Grazie all’idea e alla lunga esperienza, Stagnoli ha sviluppato un’ampia gamma di prodotti propri, sia per l’accessoristica per cancelli automatici, che per la segnaletica industriale.

La nostra storia

Ripercorri le tappe che hanno segnato il nostro cammino

L'inizio

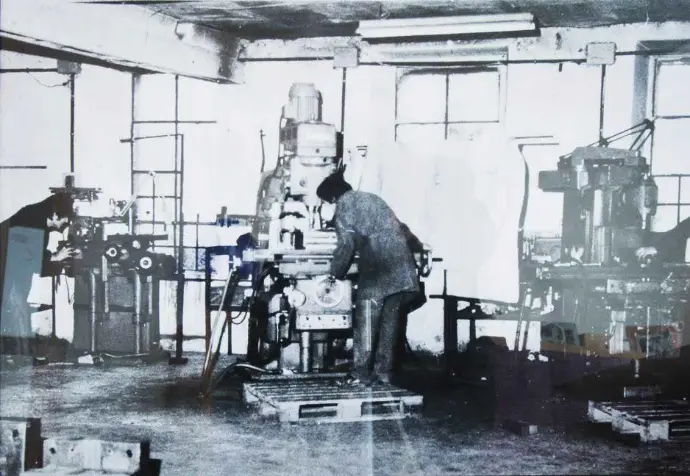

In 1981, in a warehouse of 250 square meters, with 2 employees and 3 injection presses, our company history began, immediately focused on "technical" molding.

I primi ingranaggi e i primi tecnopolimeri

We strengthen and organize the design and production of gears on drawing and we create the first standard product catalog. The collaboration with the Politecnico di Milano certifies and develops skills in transmissions and in the design of gears applied to technopolymers

Il nuovo reparto

The company is enriched with a new department dedicated to the production and maintenance of molds. In the same year we filed the patent for the nylon rack with steel core, our flagship product that has made us famous throughout Italy and abroad.

Un passo alla volta!

Our factory expands from 250 to 2000 square meters. Our company moves to a new location and the production department is completed with the addition of 4 presses and cutting-edge machinery and equipment.

L'espansione

The company further expands its production spaces with the construction of a factory of 7,000 square meters, of which over 4,500 square meters used for production. Furthermore, a department dedicated to mechanical machining (CNC) on our products is added to the production chain, in particular post-molding turning and milling.

Reparto di Ricerca e Sviluppo

Our company invests in Research and Development by organizing training courses for its staff in the field of production and design.

L'azienda cresce

We prove to be one of the most qualified and most qualified gear and transmission manufacturers

Gli occhi verso il FUTURO

In the last 5 years we have faced challenging challenges and projects that have led us into new markets and application sectors, with transmission parts and technical details modeled in a more precise and resistant way. Thanks to the tests on the life of the gear wheels, we are among the first companies in Europe to have experimental data on mechanical resistance and wear.