LA NOSTRA STORIA

Dal 1981

Stagnoli nasce negli anni ‘80. Come tutte le imprese vincenti, anche Stagnoli è nata da un’idea, l’idea di utilizzare le materie plastiche per applicazioni meccaniche come le cremagliere per cancelli. Questa idea è stata perseguita da sempre sia dal sig. Francesco Albiero, che tuttora offre all’azienda le sue preziose consulenze e il suo prezioso know how, sia dallo staff tecnico-commerciale, che oggi rappresenta il cuore pulsante di Stagnoli. Grazie all’idea e alla lunga esperienza, Stagnoli ha sviluppato un’ampia gamma di prodotti propri, sia per l’accessoristica per cancelli automatici, che per la segnaletica industriale.

La nostra storia

Ripercorri le tappe che hanno segnato il nostro cammino

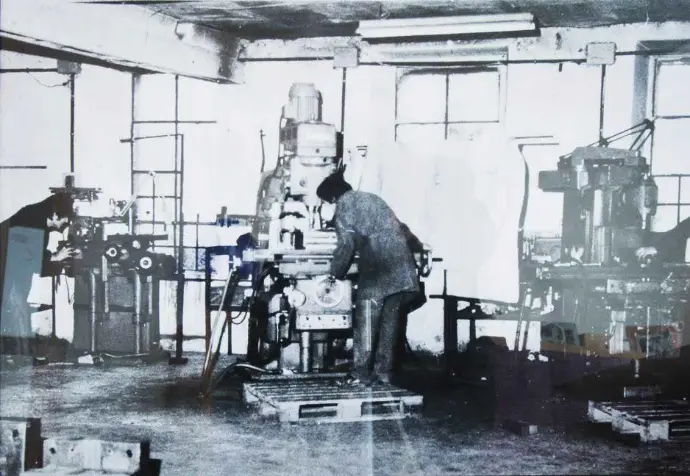

L'inizio

Nel 1981, in un capannone di 250 mq, con 2 dipendenti e 3 presse ad iniezione, inizia la nostra storia aziendale, da subito incentrata su uno stampaggio "tecnico"

I primi ingranaggi e i primi tecnopolimeri

Rafforziamo e organizziamo la progettazione e produzione di ingranaggi su disegno e creiamo il primo catalogo prodotti standard. La collaborazione con il Politecnico di Milano certifica e sviluppa competenze nelle trasmissioni e nella progettazione di ingranaggi applicate ai tecnopolimeri.

Il nuovo reparto

L'azienda si arricchisce di un nuovo reparto dedicato alla produzione e manutenzione stampi. Nello stesso anno abbiamo depositato il brevetto per la cremagliera in nylon con anima in acciaio, il nostro prodotto di punta che ci ha reso famosi in tutta Italia e all'estero.

Un passo alla volta!

Il nostro stabilimento si espande da 250 a 2000 mq. La nostra azienda si trasferisce in una nuova sede e il reparto produttivo viene completato con l'aggiunta di 4 presse e macchinari e attrezzature all'avanguardia.

L'espansione

L'azienda amplia ulteriormente i propri spazi produttivi con la costruzione di uno stabilimento di 7.000 mq, di cui oltre 4.500 mq adibiti alla produzione. Inoltre, alla filiera produttiva si aggiunge un reparto dedicato alle lavorazioni meccaniche (CNC) sui nostri prodotti, in particolare tornitura e fresatura post-stampaggio.

Reparto di Ricerca e Sviluppo

La nostra azienda investe in Ricerca e Sviluppo organizzando corsi di formazione per il proprio personale nel campo della produzione e del design.

L'azienda cresce

Dimostriamo di essere uno dei produttori di ingranaggi e trasmissioni più qualificati.

Gli occhi verso il FUTURO

Negli ultimi 5 anni abbiamo affrontato sfide e progetti impegnativi che ci hanno portato in nuovi mercati e settori applicativi, con organi di trasmissione e dettagli tecnici modellati in maniera più precisa e resistente. Grazie ai test sulla vita delle ruote dentate, siamo tra le prime aziende in Europa a possedere dati sperimentali sulla resistenza meccanica e all'usura.